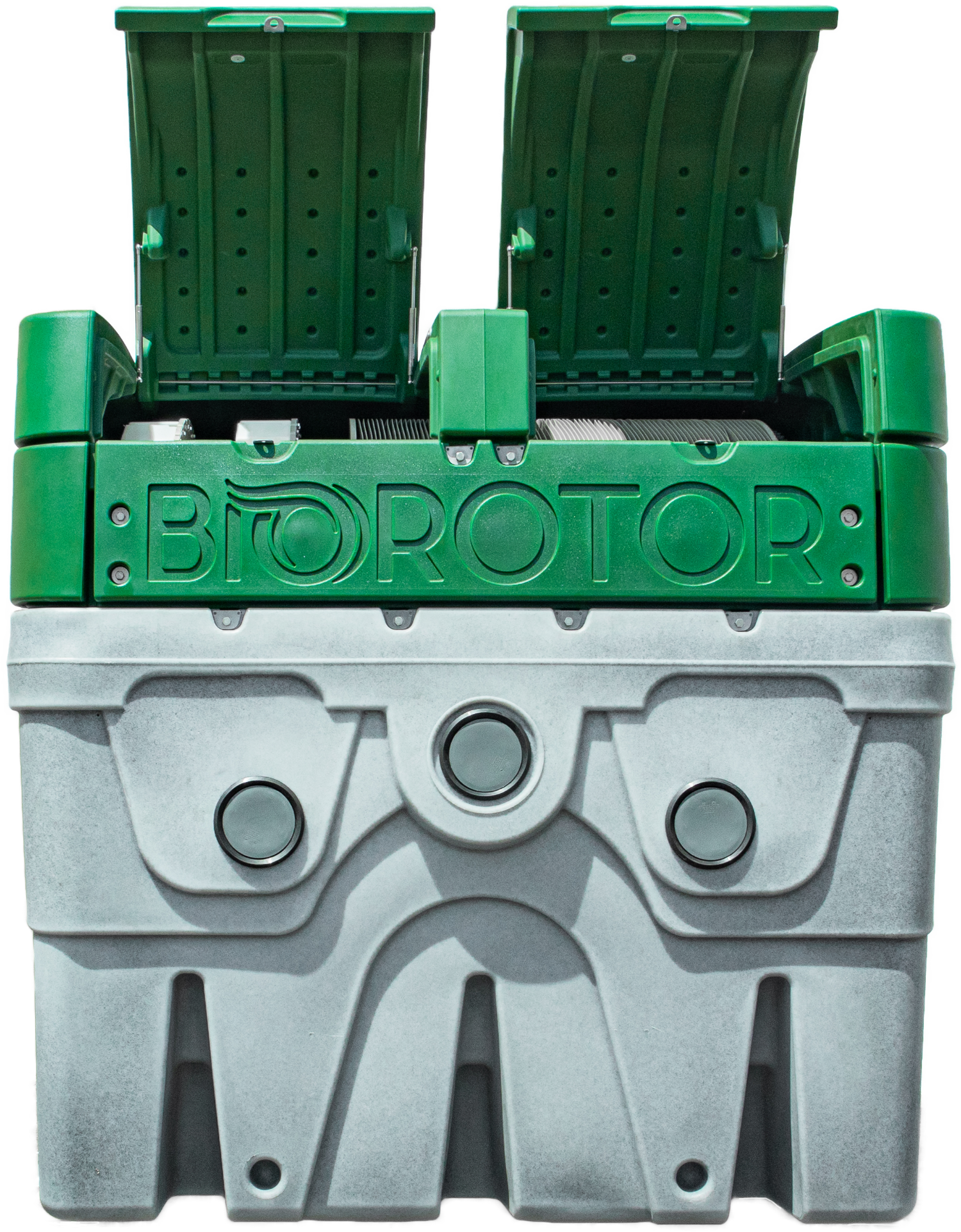

ROTATING BIOLOGICAL CONTACTOR,

MADE BETTER.

BIOROTOR is a fully automatic, modular, wastewater treatment system, that was expertly developed for communities up to 10.000 PE.

It was created by an amazing team of engineers, led by an RBC expert who has spent 30 years designing and optimising the technology.

We took the best parts of this tried-and-tested technology, but replaced or improved every element that could create an issue, making BIOROTOR the most reliable, risk-free, easy-to-operate and cost-effective RBC ever created.

BIOROTOR IS IDEAL FOR

SIMPLY INGENIOUS

Our Favourite Projects

Meeting Local Regulations: The BIOROTOR Solution for Perocseny Pension’s Wastewater Treatment System in Hungary

Perocseny Pension, a small pension located in the Northern hills of Hungary's National Park, needed to find a decentralized wastewater treatment solution that would help them meet the current wastewater regulations while being extremely compact.

Investing in Sustainability: Replacing an Old Wastewater Treatment System With a New BIOROTOR Installation at Luvigny

In today’s world, municipalities are under immense pressure to not only provide high-quality wastewater treatment for their residents, but to do so in a sustainable and cost-effective way. Older wastewater systems can often be energy intensive, expensive to maintain, or ineffective, which is why the municipality of Luvigny decided to replace their existing system with a new BIOROTOR installation.

ENERGY CONSUMPTION OVER 5 YEARS IN KWH FOR A 600 PE INSTALLATION

The Lowest Energy Requirement

The Lowest Energy Requirement

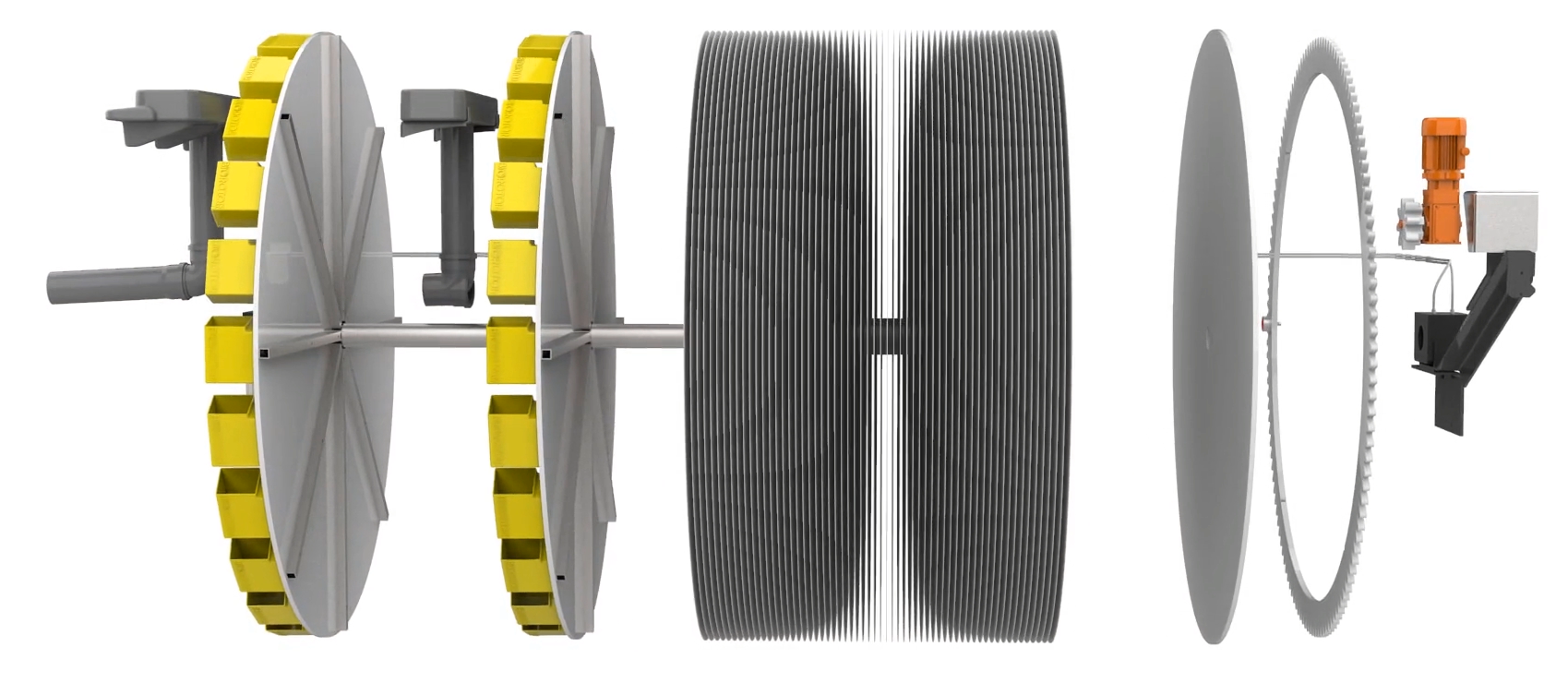

Thanks to its unique ring gear drive, BIOROTOR has the lowest energy requirement per population equivalent, compared to other commercial wastewater treatment technologies.

For example, the energy consumption of BIOROTOR representsonly 27% of the average energy consumption of an equivalent-capacity Activated Sludge system, or a SBR system. This means that by choosing BIOROTOR you can save up to 70% on energy cost per year.

ENERGY CONSUMPTION OVER 10 YEARS IN KWH FOR A 600 PE INSTALLATION

The Lowest Energy Requirement

Thanks to its unique ring gear drive, BIOROTOR has the lowest energy requirement per population equivalent, compared to other commercial wastewater treatment technologies.

For example, the energy consumption of BIOROTOR representsonly 27% of the average energy consumption of an equivalent-capacity Activated Sludge system, or a SBR system. This means that by choosing BIOROTOR you can save up to 70% on energy cost per year.

ENERGY CONSUMPTION OVER 5 YEARS IN KWH FOR A 600 PE INSTALLATION

Upgrade Your Existing System

Because recycling is a second nature for us, we designed BIOROTOR keeping in mind that some systems just need a little upgrade to have a second life.

With BIOROTOR, you can modernize or replace an existing system to transform it into a state-of-the-art sewage system which is cost-effective, robust, and super easy to maintain .

Whatever you need, we got you covered.

Upgrade your existing system

Upgrade Your Existing System

Because recycling is a second nature for us, we designed BIOROTOR keeping in mind that some systems just need a little upgrade to have a second life.

With BIOROTOR, you can modernize or replace an existing system to transform it into a state-of-the-art sewage system which is cost-effective, robust, and super easy to maintain .

Whatever you need, we got you covered.

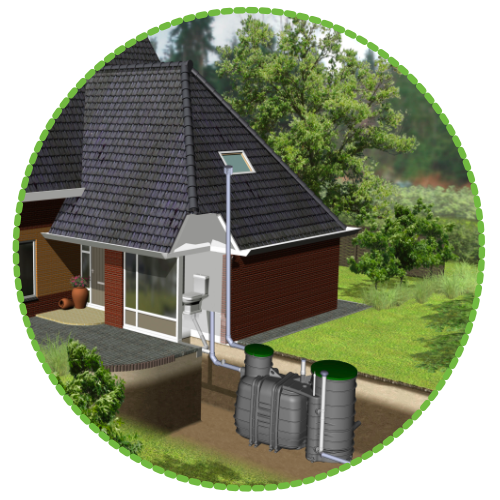

If you need a smaller & non-electric treatment plant,

we have also a solution for you, no matter the size!

Visit the BIOROCK website to learn more about our sustainable sewage treatment plants.